If you are the owner of an operating railroad as I am of the Minneapolis & Northland Railroad Company (M&N) you may have to take time away from increasing the freight car fleet and turn to other work required on the railroad. This was the case this past month as the town of Randolph had its industry base growing. A Commander elevator, the new industry to be built in Randolph, Minnesota, needed track installed to become part of the customer base being served by of the Minneapolis & Northland Railroad Company. And, the Chicago Great Western (CGW) Interchange track would be expanded.

|

| Randolph, Minnesota prior to Commander Elevator. (Click or tap on this or any image to enlarge) |

To enable an area for the Commander Elevator and CGW Interchange to expand new benchwork was built. As for other sections of the railroad, L-girder benchwork was constructed as easy to construct and goes together quickly.

|

| L-Girder benchwork assembled and attached to prior benchwork. |

Long and short L-girders connect to the legs and short L-girders are built to sit above the long L-girders to attach 1/2 inch plywood top with screws via the L-girder cap. Another advantage of the short L-girders riding on the long L-girders is they can be moved at anytime. Why would they have to be moved? After tracks are laid on benchwork top, the L-girder might be in the area a switch machine needs to be installed.

|

| View of short L-Girders |

After benchwork was completed and attached to existing benchwork, it was painted for finished look. I like to use a grey-black latex paint. I like a black color for if you study colors you find the eye does not like black and will move to another location - the scenery on the benchwork. In addition, painted benchwork helps prevent lumber absorbing moisture during summers when the humidity is a factor. Even with dehumidifiers controlling humidity it is best to be considered.

|

| Benchwork painted. |

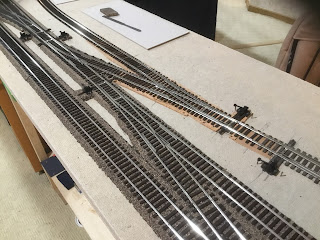

Once the paint on the benchwork is dry, Homasote, a cellulose-based fiber wall board, that was painted a brown earth color latex prior to install, is attached to the plywood with nails. Nails that are angled when put in are used rather than glue to prevent sound transfer from ballasted track on Homasote to benchwork. Benchwork fascia was now installed and painted to match a grey-black color of benchwork I use. With the Homasote installed a track location center line is drawn on the Homasote and Midwest cork and track is installed. The Midwest cork was installed with wire nails and the Walthers track is installed with Micro Engineering track spikes.

|

| Painted Homasote attached to benchwork. |

The CGW Interchange was than ballasted with a mix of white and black foundry sand and affixed with Elmer's white glue thinned with tap water. The adhesive mixture of 1/3 white glue and 2/3 tap water with a few drops of dish washing soap added is prepared in an Elmer's white glue container which also acts as applicator. The ballast prior to adding the thinned white glue for adhesion must be lightly sprayed with wet water, tap water with a few drops of dish washing soap added, or the ballast will bubble and not stay in place when the water thinned white glue is applied..

|

| Ballast and tools used for application. |

And, since I do like doing scenery I could not resist adding some Woodland Scenics Blended Turf, Green Blend, T 49, and SceneMaster Grass Tufts, 949-1101, along the Anchor Glass Plant wall.

|

| Ballast to CGW track extension and scenery added. |

With the Chicago Great Western Interchange increased in length and elevator track in place. The elevator, a combination of two Walthers Cornerstone kits, Farmers Cooperative Rural Elevator, 933-3036, and Trackside Oil Dealer, 933-4059, assembled at my work desk with MEK could be located on the benchwork. All roofs on main elevator and sheds were not and will not be glued to allow access to interior. The office and scale cover portion is also not glued to allow removal later. On the attached storage sheds, scale and office portion, a concrete foundation of .060 sheet styrene foundation was added to replace the wood floor supports in the kits. The concrete foundation was common on elevators rather than wood floor supports in the Midwest, specifically on elevators I saw.

|

| Elevator after assembly installed. |

|

| Elevator after assembly installed. |

Another major change to the wood clapboard elevator and one storage shed was needed. The wood clapboard needed to be replaced with corrugated aluminum sheathing as common on all elevators I saw in the Minnesota area I model. I was going to use Campbell Scale Models aluminum corrugated sheathing; however, the three packages I had in stock would only provide a tiny portion of aluminum sheathing needed to cover the main elevator body and one storage shed. A further search through building materials I had in stock produced three packages of plastic sheathing I had purchased from Alpine Division Scale Models years before.

|

| Plastic sheathing for elevator. |

My calculations for the needed sheathing also showed the plastic sheathing was not enough sheathing. Therefore, I decided I would make additional sheathing to match the plastic sheathing. To make additional needed sheathing I used a section of the plastic sheathing as a master and placed heavy duty kitchen tin foil over a section of cut plastic siding . A dry transfer application tool with the plastic end was run over the tin foil pressing it into each groove in the plastic sheathing to make embossed sheathing like the plastic one. The embossed made sheathing was used on the trackside back wall of elevator shed on the left and bottom two rows of sheathing on the main elevator body. A photo is included below to show the tools used to make the needed sheathing and tools used to apply the sheathing.

|

| Tools used to make tin foil sheathing and to apply foil and plastic sheathing. |

The plastic sheathing was cut into strips eight feet scale wide. These strips were cut again into sections 50 inches scale wide making an individual aluminum sheathing sheet 50 inches wide and 8 feet in length matching prototype dimensions. The plastic panels were applied with Testors Tube Cement spread across the back of each with a toothpick. The sheets were overlapped at the edge of each when installed providing a viewable installed sheet on the elevator 48 inches wide as on prototype. The Testors Tube Cement was used rather than MEK as the on the first two siding sheets installed the MEK caused the sheets to turn black in sections. A reaction I did not want.

|

| Testors Tube Cement |

|

| Plastic sheathing installed on two areas. Note black areas in plastic siding on shed. |

|

| Plastic sheathing installed on two areas. |

The corrugated sheathing panels made using the heavy duty kitchen tin foil were installed with 3M, 465, 3/4 inch high adhesive transfer tape.

|

| Tin foil made sheathing installed with transfer tape. Transfer tape covering not yet removed in upper right corner. |

Sheathing application took what seemed an eternity; however, I kept forcing myself to remember “Model Railroad is Fun” until the tedious work of aluminum sheathing install was finished. Once finished the sheathing was hand painted Model Master Aluminum, 1781, the white styrene concrete foundations Polly Scale Concrete, F414317, the windows and doors Vallejo Model Color Cavalry Brown, 70.982. The steel roofs were not painted; however, they were weathered lightly with Pan Pastels, Burnt Sienna Shade, 740.3.

|

| Elevator sheathing, doors and windows painted. |

In addition, the track to the elevator was ballasted and scenery added. With elevator set in place a pencil used to draw a footprint line around it. The elevator was removed to add the landscaping surrounding the elevator complex. The landscaping was done with Woodland Scenics Blended Turf , Green Blend, T49, for grass and sifted common sand for roads. In addition, the roads had some dirt obtained from the home plate area of the local baseball field applied to them with a tea strainer. All scenery materials were glued in place as the tack ballast with water thinned white glue mixture of 1/3 glue and 2/3 tap water with a few drops of liquid dish washing soap added made in a Elmer's glue container. The Woodland Scenics grass is a temporary base that looks good until static grass is applied over it.

|

| Scenery materials and tools. |

The Randolph Elevator while waiting for signs and other details if needed is ready for rail service provided by the Minneapolis & Northland Railroad Company. A new customer is always welcomed.

|

| Randolph Commander Elevator ready for rail service. |

|

| Randolph Commander Elevator ready for rail service. |

|

| Randolph Commander Elevator ready for rail service. |

I want to say, “Thank You” to Mike Schmitzer for providing steel and aluminum roof sheet sizes. A “Thank You” to Dave Nelson for suggesting the use of transfer tape to attach plastic siding. A “Thank You “ to Ron Christensen for sharing his presentation on modeling steel and aluminum roofing and siding.

Thank You for taking time to read my blog. You can share a comment in the section below if you choose to do so. Please sign your comment with your name if you choose to leave one. All comments are reviewed and approved before they appear. Please share the blog link with other model railroaders.

Lester Breuer

.