A food processing industry, Food Producers, a recently added Minneapolis & Northland Railroad Company (M&N) customer needs concentrated vinegar to add to food products to improve taste. Since vinegar is an acid that is corrosive, a vinegar tank car constructed of wood was chosen rather than a metal tank that required an expensive lining. To be able meet the new service need a resin Sunshine Models, Standard Brands, Inc. wood vinegar tank car, kit 60.3, was added to the roster. The vinegar tank car kit was given to me by my good friend Steve Steele. Steve purchased two identical complex kits at a flea market at a very reasonable price and after building one gifted me the other.

The prototype Standard Brands, Inc. wood vinegar tank cars with reporting marks SBIX, series 1448 to 1646, AAR class TW, had an early horizontal wood tank, held together together by a series of rods under tension applied with cast clamps. The tank rode on a set of saddles mounted on a welded fish belly underframe. The wood tank was protected by end frames fabricated of “H” beams, channels and wood. Two diagonal bands (“X” braces) ran from the end frame to the opposite bolster to protect against movement. The Prototype Data Sheet (PDS) in the kit states most vinegar tank cars rode on planked cast side frame trucks.

|

| Photo of SBIX 1617 on Sunshine Models PDS, Bob's Photo. (Click on this or any photo to enlarge) |

In addition to the above photo that can be purchased from Bob’s Photo, additional vinegar tank cars photos to aid in the build of the tank car are found in Prototype Data Sheet #60, “Fleischmann’s and Standard Brands’ Wood Horizontal Tank Vinegar Car”, provided in the kit. Photos are also available in Ted Culotta’s article discussing his construction of this kit in his “Essential Freight Cars” series in Railroad Model Craftsman (March 2005).

The first step in the build of the Sunshine Models resin vinegar tank car is the tank assembly. A task that requires a resin cast rolled tank shell be glued at the bottom seam to the form tank (hollow tube) into which the ends are glued. The tank ends require a large amount of material to be removed to fit inside the tank shell. Therefore, you have to be very careful to keep the ends round when removing material. Today I believe the tank would be cast as one piece making for easier car assembly.

Looking at the tank shell, I thought the hollow assembled tank shell might deform or be easily be damaged in the future unless it had an inner core - a dowel. For the dowel I cut a broom handle several inches longer than the tank and sanded it to the inner one inch diameter of the tank. An easier way to obtain the 1” dowel for the interior would be to purchase it at the local home improvement store. I inserted the dowel into the tank shell without glue for support to position one tank end and glue it in place. With the one tank end in place, I removed the dowel and cut it to the remaining inside length of the tank less the width of the other tank end. Now, I cut the dowel in half and cut off/out an area in the middle to hold the weights. The electric outlets box punch outs I use worked great here to add 2 and 1/2 ounces of weight. Of course, washers or bolt nuts would work just as well. I glued the weights to the middle of the dowel with contact cement, inserted the dowel into the tank shell without glue and installed the other end to complete the tank with a solid interior. The added weight brought the finished car with trucks installed to 3.6 ounces.

|

| Tank formed. One end installed and half of dowel inserted. Weights to be glued to wood dowel prior to inserting. |

I moved on to the tank underframe cutting out the flash which is saved as it contains various cast detail parts for the tank car. The areas where flash was removed were sanded with an emery nail board for final finish. A flora wire train line was installed next.

|

| Train line installed. Wire drill made from .032" piano wire below used to drill train line holes. |

Next the tank saddles were installed per kit instructions. After the tank saddles were installed I wrapped 100 grit sand paper around a section of a 1” dowel and sanded the saddles for a better tank fit.

|

| Tank saddles installed. |

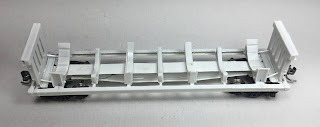

With the tank saddles mounted, the end frames were installed next. After the end frames were in place, I installed Kadee #262 coupler boxes with #148 whisker couplers and Accurail ARA cast steel with spring plank trucks with InterMountain 33” metal wheels. Both were installed with Fastenal 2-56 x 1/4” screws in holes drilled and tapped for 2-56 screws. Tichy Train Group (Tichy) plastic .020”, and Kadee .010” fiber washers were added to bolster center plate to gain proper coupler height.

|

| End frames installed. |

|

| End frames installed side view. |

Now the detailing could begin. I installed the access hatch (named porthole in kit instructions) at the top of the tank offset to the “B” end followed by the resin end and side walkways.

|

| Access hatch and walkways installed. |

Back to the underframe to complete details. I installed resin brake components brackets, plastic brake components, predrilled for piping, and plastic brake levers (both Cal-Scale) provided in kit. I added a slack adjuster to the floating lever from the parts box. Piping and brake rods followed:

- Piping from air reservoir to AB valve, .010” diameter brass wire.

- Pipe from brake cylinder to AB valve, Tichy Train Group, (Tichy) #1106, .0125” diameter phosphor bronze wire (PBW).

- Brake rods, Tichy #1106, .0125” diameter PBW.

- Chain, brake cylinder lever to brake rod, A-Line #29219, black 40 links per inch.

|

| Brake components installed. |

|

| Brake piping and rods installed. |

With underframe complete, the car body details were added beginning with grab irons and sill steps provided in the kit.

|

| Sill steps and grab irons installed. |

The most tedious and difficult part of the build, the tank bands were next. Per the instructions the install of 28 to 34 wire (rod) and 4 resin strap tanks bands was required. After studying prototype photos I laid out the position of the rod bands with tension clamps and strap tank bands in pencil on the tank. The .015” brass wire in the kit was long enough to do two rod tank bands so before adding the rod tank bands, I cut all rod brass wires in half. I deviated from the instructions on the tank bands install as I felt my method was more accurate and easier for me.

I drilled the two holes in a tank band tension clamp (resin cast part) with a #79 drill, mounted in the chuck of a 850 Dremel tool, to enable a tight fit of the .015” brass wire rod end into it. If a loose fit is preferred a #78 drill could be used. I glued the tension clamp to a location on the tank with CA. I took one of the many .015” brass wires and preformed a rod tank band on the PVC pipe provided in the kit for this task. Once I had the rod tank band preformed, I inserted one end of the rod tank band into the tension clamp and glued it with CA. I now worked the wire rod band around the tank tacking it with CA every half inch or so until I reached the other side of the tension clamp. At this point, the wire rod is longer than needed so the rod wire is cut at the half point of the tension clamp and inserted. It still might be a little too long for the hole drilled in the tension clamp so the rod wire must be taken out and a tad cut off until a proper fit is achieved. I had to do this tedious task several times on many of the rod wires as I did not want to cut off too much to have the rod wire tacked around the tank get too short.

|

| Rod and strap tank bands location marked on tank in pencil and a few bands installed. |

With the wire rod tank band install being tedious due to the number required, I took a break from installing them and installed “B” ends details. A brake gear housing (Cal-Scale in kit) was installed per photos after the molded on chain was cut off as too short to go below the end walkway. An A-Line, #29219, black 40 links per inch section of chain was installed. A Kadee Adjax brake wheel was installed. I added the uncoupling lever bracket and eye bolt bent from Tichy #1101, .010” diameter wire, for the later to be added uncoupling lever.

|

| Brake housing, Ajax brake wheel, new chain and uncoupling lever brackets installed. |

Back to finishing the tank bands. Finally, the wire rod tank bands were installed.

|

| All rod tank bands finally completed. |

The install of the strap tank bands followed. Prior to their install, the tank saddles mounted over the bolsters had the end recess painted Vallejo Black #70.950, and the end plate with oval hole installed. The tension bracket on the tank band was drilled with a #79 drill and a .015” brass wire, about an inch long, was inserted and glued for the mounting rod. A strap tank band rod end was installed in a hole drilled into a underframe cross member on one side of the tank and glued. The strap band was then carefully wrapped around the tank and the rod on the other end installed into a hole drilled into the same bolster on the other side.

|

| Strap tank bands installed. Note plate on end of tank saddles mounted over bolsters. |

Now to complete the remaining tank detailing. A retainer valve with mount (cast resin kit part) was drilled for retainer line and installed near “B” end on the left side. The brackets for the retainer line were the two supplied kit eye bolts. And, the retainer line, .008” brass wire provided in the kit was installed. Tichy handrail brackets from Tichy Tank Detail set #3007, were installed per photos; however, the end handrail brackets I bent from Tichy #1101, .010” PBW. The .019” brass wire handrails were installed. The kit provided resin cast elbows I felt were too large so I replaced them with elbows made with MEK Goop (plastic melted in MEK). Another solution for the corner elbows would be to bend them from appropriate size tubing.

|

| Retainer line installed. And, handrails installed. |

|

| Handrails with Tichy and end made brackets installed. Elbows made with MEK Goop. |

|

| "B" end with details except for uncoupling levers installed. |

Once the hand rails were installed, the diagonal (“X”) braces mounted between the top of the end frame and bolster on the other end were installed. The resin cast braces were replaced with braces made from Evergreen # 8106, 1” x 6” strip styrene with .025” styrene rod (kit) glued to them for the brace end rods were installed. The clamp attached where the “X” braces meet is a resin part in kit. With “X” braces installed, side lettering boards sanded to tank shape and Tichy diamond shape tack boards (replaced resin cast ones in kit) from Tichy Tank Car Detail set #3007, were installed.

|

| "X" braces and side lettering boards installed. Tension clamps, other details and trucks painted. |

All that remained to do was to install the uncoupling levers, bent from Tichy #1106, .1026” PBW. The uncoupling levers were installed after the car was painted.

|

| Uncoupling lever installed. |

In the paint shop the tension clamps for the wire rod tank bands, coupler pockets, trucks and brake components were hand painted with Model Master Aluminum (see "X" braces photo above). Once dry, the car was sprayed with Vallejo Model Air Aluminum #71.062. Again when dry the car was sprayed with Vallejo Gloss Varnish, 70.510, to provide a gloss base for decals.

|

| Car painted with Vallejo Aluminum. |

|

| Car painted with Vallejo Aluminum. |

Rail Graphics decals printed in black, lettering color used in the 1950s, were applied using MicroScale Micro Sol setting solution. I chose number 1641 that had a listed capacity of 100,000 and was still in service based on a 1955 Official Railway Equipment Register (ORER). Some of the decal car numbers on the decal sheet are for 80,000 capacity cars and one would not know that unless an ORER was used to check the numbers. The number 1641 was two decals cut from the numbers and the date 2-54 replaced the original date on the lower side lettering board. The car data decal for the placard board on the end of the car was not printed the correct size; however, I used it as printed.

|

| Decals provided in kit applied. |

|

| Decals provided in kit applied. |

Once decals were dry the car was sprayed with Vallejo Matt Varnish #70.520. And, when the Matt varnish coat was dry, a weathering coat was sprayed on the car using a mix of Vallejo Model Color #70.862 Black Grey, 2% or one drop and thinner 98% or 40 drops. In addition, Pan Pastels Payne’s Extra Dark Grey, 840.1 was applied in various areas with a micro applicator.

|

| Car weathered with air brush and Pan Pastels. |

|

| Car weathered with airbrush and Pan Pastels. |

After weathering with air brush and Pan Pastels, SBIX 1641 was ready for service on the Minneapolis & Northland Railroad Company, “Serving today, Shaping tomorrow.” A car card was made for SBIX 1641, the final step to put it in service on the Minneapolis & Northland Railroad Company Railroad.

|

| Vinegar tank car SBIX 1641 spotted at Food Producers, Inc. |

|

| Vinegar tank car SBIX 1641 spotted at Food Producers, Inc. |

I want say, “Thank You” to Steve Steele for the Sunshine Models Vinegar Tank Car kit. A challenge to build; however, I am pleased to have had the opportunity to experience and learn from. And, like Steve I prefer not to build another.

Thank You for taking time to read my blog. You can share a comment in the section below if you choose to do so. Please sign your comment with your name if you choose to leave one. Please share the blog link with other model railroaders.

Lester Breuer