When I became aware of the new 3D printed Minneapolis & St. Louis (M&STL) general service 42 foot gondola, resin kit 220801, produced by Northwoods Models, Soo Parts, I ordered two. When the gondola kits arrived, one immediately went to the workbench and the other to the to build kits cabinet. I wanted to build the 3D printed kit immediately to enter coal hauling service on my Minneapolis & Northland Railroad Company railroad as the gondolas did on the M&STL. A second reason was to test the new Badger 3D Prime two step primer to fill striations on models.

|

| M&STL Gondola 30315 in coal hauling service Doug Harding Collection (Click or tap on this or any image to enlarge) |

The prototype Minneapolis & St. Louis (M&STL) general service, drop bottom gondolas were purchased from General American Transportation Corp. in 1947. The M&STL assigned the 249 built GS class gondolas to series 30001-30499, odd numbers only. The gondolas per the 1953 January Official Railway Equipment Register (ORER) were 42 feet 4 inches in length, all steel with 16 drop bottom doors. The cars had a unique inset on the bottom of the side sheet. As delivered, the gondolas were painted black with white lettering including slogan, “The Peoria Gateway.” A nice prototype photo in the instructions and in the 1949-1951 Car Builders' Cyclopedia (Simmons-Boardman Publishing Corporation, 1949) was used for the build and lettering. In addition, Doug Harding provided photos and a car diagram for my build.

|

| 1949-1951 Car Builders Cyclopedia Courtesy of Doug Harding |

|

| Gondola Diagram Courtesy of Doug Harding |

I began the build as with all kits reviewing the car body (well printed) and detail parts (well printed) to decide which I would use to build the model. Even after flash is removed from the kit parts they are kept in the box to prevent entering the “black holes” surrounding my workbench.

|

| Gondola kit parts before flash removal. |

After I finished my parts review I removed underframe flash and installed the underframe. I carved off the printed on piping for brake components. The kit provided weight (neat kit feature) was installed into the gondola body. The car body with weight when placed on a digital postal scale showed 3.2 ounces. An acceptable weight for the gondola when in operation on my Minneapolis & Northland Railroad Company.

|

| Gondola weight and underframe installed. |

The underframe has brake components molded on the center sill which I would have preferred was not the case. I cut the brake cylinder off to allow for drilling to install a brake cylinder piston from Tichy Train Group (Tichy) set #3013 and piping. The same had to be done for the AB valve to drill for piping. And, later the AB valve location had to be moved from the center to the edge of the center sill to properly position the brake rod between brake levers.

|

| Piping install started. |

The install of the interior floor to cover the kit installed weight followed.

|

| Gondola interior floor installed. |

I went back to the underbody work. I drilled and tapped coupler pocket pads and bolster center plate for 2-56 screws. The kit is designed for Kadee #178 couplers; however, they are not included. Kadee #178 couplers and Accurail ARA cast steel with spring plank and InterMountain 33” metal wheels were installed. Install of the following items not in the kit followed:

- train line, .018” diameter floral wire

- Brake cylinder lever, Evergreen #8108, 1” x 8” strip styrene

- Floating lever, Evergreen #8106, 1” x 6” strip styrene

- Brake piping from air reservoir to control valve, Tichy #1101, .010” diameter PBW

- PBW stands for phosphor bronze wire

- Brake pipe from brake cylinder to control valve, Tichy #1106, .0125” diameter PBW

- Brake rods, Tichy Train Group (Tichy) #1106, .0125” diameter PBW

- Brake rod clevises, MEK Goop

- Chain, Precision Scale #48553, 34 links per inch

- Bell crank and Clevis, Tichy set #3013. Clevis has brake rod cut off.

|

| Underbody brake work installed. |

|

| Installed brake work viewed from side. |

Now I moved to the sides and installed the grab irons. I did not use the 3D printed grab irons in the kit. I used Tichy #3015, 18” drop type grab irons installed in #79 drilled holes instead.

|

| Grab irons installed. |

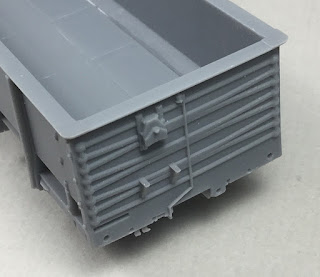

Upon completion of the underbody work I moved on to the “B” end work. I carved off the printed on retainer valve and line.

|

| Printed on retainer valve and retainer line that I cut off. |

Once the carving of retainer valve and line was done I installed the following details:

- ladders (kit)

- brake platform, Plano set #11322

- Brake gear chain, Tichy set #3013

- Brake rod, Tichy #1102 .015” diameter PBW

- Retainer valve, Precision Scale #31796

- Retainer line and brackets, Tichy #1100, .008” diameter PBW

- End winch mechanisms (kit) on sill corners

- Brake chain guide (kit) next to coupler pocket

- Grab irons, straight and sill custom bent from Tichy #1106, .0125” diameter PBW

- Brake wheel, kit

|

| Majority of "B" end details installed. |

Next back to the sides where I installed the chain winches (kit) on brass rods (kit). In addition, I installed the kit printed sill steps.

|

| Door winches and sill steps installed. |

After install of the kit sill steps I broke one off. So I cut off the remaining three and soldered up new brass sill steps. I used Detail Associates #2524, .010” x .030” flat brass bar to solder up new sill steps and bend the angle on them with a pliers. The newly made brass sill steps were installed. When I contacted Soo Parts regarding molded on brake components, I was told I could have had the sill step replaced upon request.

|

| Sill steps made from brass and installed. |

Next uncoupling levers were installed. I bent my uncoupling levers from Tichy #1106, .0125” diameter PBW with styrene brackets fashioned from Plastruct #90502 1/16” styrene angle.

|

| Uncoupling levers installed. |

|

| Note uncoupling lever bracket. |

The build was finished except for paint and lettering, so off to the paint shop. I was excited to be at this point as I was able to use the new Badger 3D Prime 2 step Translucent Surface Smoother (striation filler) for common 3D printed materials that I had purchased directly from Badger. The instructions on the bottle label state, “apply with a .5 or larger nozzle airbrush at 20-30 psi ….holding airbrush 4-6” from item.” The 3D Prime, part one, is to be airbrush ready; however, I found it was not. I had to thin the product 50/50 with thinner to spray properly. I did not have Badger thinner so I used Polly S airbrush thinner I had on hand. I let the model dry overnight.

|

| Car airbrushed with Badger 3D Prime part one. |

The next day I airbrushed the dry gondola with 3D Prime part two. As with part one, I had to thin the product 50/50 with thinner to spray properly. After I let it dry and inspecting the gondola I found the printing striations were not filled as I believed they would be. I believe, my having to thin the product and possibly not having Badger thinner produced the results I obtained.

|

| Car airbrushed with 3D Prime part two. |

After my inspection of the car body I airbrushed the car underbody Vallejo/Micro-Mark Model Air Tarnished Black #29022X2 and the car body Vallejo Model Color Black 70.950. Once the paint was dry, the car body was sprayed Model Master Gloss Clear Acryl, #4638, to have a gloss base for decal application. While the gloss finish was drying I hand painted the trucks with Vallejo/Micro-Mark Model Air Tarnished Black #29022X2. And, I reviewed the decals in the kit printed by Circus City Decals to choose the car number 303357.

|

| Underbody airbrushed tarnished black. |

|

| Car body airbrushed Vallejo Model Color black. |

|

| Car body airbrushed Vallejo Model Color black. |

After gloss finish was dry, decals were soaked off in distilled water and applied to the car body where MicroScale Micro Set had been applied with a brush. After decals were applied in the Micro Set and positioned the edges had MicroScale Micro Sol applied. Any excess solution was sucked away with the torn edge of a paper towel. When dry, car body was sprayed with Model Master Gloss Clear Acryl #4638, to better hide decals edges. Again, the car body was sprayed with Model Master Flat Clear Acryl, #4636, flat to protect decals and provide a flat finish for weathering when applied. Finally, the car body was airbrushed Vallejo Satin Varnish 70.522

|

| Decals provided in kit applied. |

|

| Decals provided in kit applied. |

My last step before putting Minneapolis & St. Louis gondola 30357 in service was to weather the car with Pan Pastels. Pan Pastels Paynes Grey Extra Dark 840.1 was used on the car body and lightly over safety appliances on car body. Neutral Grey 820.5 was used as highlight on car body and interior areas. Burnt Sienna Shade 740.3 was used to simulate the rust areas.

|

| Car weathered with Pan Pastels. |

|

| Car weathered with Pan Pastels. |

|

| Car weathered with Pan Pastels. . |

|

| Car weathered with Pan Pastels. |

Minneapolis & St. Louis gondola 30357 was ready for service on the Minneapolis & Northland Railroad Company, “Serving today, Shaping tomorrow.” A car card was made for M&STL 30357, the final step to put the cars in service on the Minneapolis & Northland Railroad Company Railroad.

|

| M&STL Gondola 30357 spotted at J.D. Owen Coal in Little Chicago, MN. |

|

| M&STL Gondola 30357 spotted at J.D. Owen Coal in Little Chicago, MN. |

|

| M&STL Gondola 30357 spotted at J.D. Owen Coal in Little Chicago, MN. |

I want to say, “Thank You” to Doug Harding for providing photo and car diagram to help with this build and upgrade. Definitely appreciated as without his help this build would have been more difficult.

Thank You for taking time to read my blog. You can share a comment in the section below if you choose to do so. Please sign your comment with your name if you choose to leave one. Please share the blog link with other model railroaders.

Lester Breuer

.