I have built Red Caboose, kit RC-2209d, a 42 foot flat with fish belly side sills, lettered for the Great Northern, GN, numbered 69958 (original number 69158), class FM. The flat car depicts the basic USRA design with modifications. As with every kit I begin my search for data and photos of the prototype. In my resources, only my copy of a reproduction of the January 1953 Official Railway Equipment Register (National Model Railroad Association, 1996) provided the following: class FM, series 69000 to 69299, and outside dimensions of length 43 feet and width 9 feet 6 inches. A good start as the Red Caboose flat has similar dimensions.

There had to be more data I could obtain so I contacted two GN modelers: Rich Remiarz and Bob Heninger. Both Rich and Bob responded that the Red Caboose flat is best used to model the GN 69500 to 69999 series. Rich provided me with an article, “Modeling Project”, by Ted Frandel describing using this Red Caboose kit to model the GN, 42 foot flat car, 69500 to 69999 series of flat cars. The article states the cars were built in 1929 and lasted into BN merger in revenue service. In addition, Rich provided a diagram for these cars from the GN Freight Diagram Book. The diagram has a note stating these cars were built as logging flat cars, class FL; however, 52 cars in this series had the bunks removed and class changed from FL to FM. And, this flat cars series rode on Dalman trucks. Bob made me aware there is a photo of a flat car in this series in the revised edition of Great Northern Lines East ( Signature Press, 2001). I do have the first edition of this book; however, not the revised edition so no photo to work from for the build.

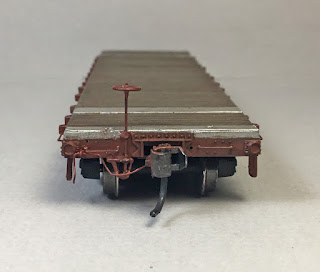

I began the build of the the flat car with the underbody. I drilled the coupler pockets, pocket covers, and bolster center plate for 2-56 screws. I cut a piece of .040” thick sheet lead to fit the entire under body of the flat car to replace the lighter kit provided kit weight. The sheet lead weight was glued to the under body using Formula 560 canopy glue followed by the underframe using CA. Kadee #148 couplers were installed with Athearn #99000, 2-56 x 1/8” screws. Accurail ARA cast steel with spring plank trucks in the kit, later replaced with the correct Tahoe Model Works, TMW-101, Dalman trucks, were installed with Fastenal 2-56 x 1/4” installed. The weight, plus couplers and trucks installed weighted the car to 2.0 ounces.

|

| Sheet lead weight, couplers and trucks installed. |

Ted Frandel in his article tells how to make cuts in underframe to increase distance between truck centers from 32 feet to 33 feet plus inches making it closer to the prototype which was 33 feet 8 inches; however, the prototype car length was 43' 8" and the model is 42', the 1" 8" difference. I did not change the distance between truck centers as on the shorter length model it moves the trucks too close to end sill to cause operation problems.

Next, I installed the twelve stake pockets in the kit on each side. Ted Frandel in his article suggests using Tichy stake pockets instead. If you do, you will have to remove mounting pins as they will not mount in the holes provided for stake pockets. After finishing the stake pockets I installed the grab irons bent from Tichy, #1101, .010” diameter phosphor bronze wire (PBW) on the sides and ends. The molded on sill steps were cut off and A-Line #29000, sill steps installed. Mounting of hand brake, drop shaft with Ureco brake wheel, provided in the kit on the “B” end followed per the kit instructions. After mounting, I cleaned up the interior of the brake step with a broach.

Time to do something to the deck to attempt to achieve a more realistic looking one. First I used a hobby saw to make cuts between the ends of each board. Next, I roughed up the simulated wood deck boards with coarse sand paper. My favorite weathering agent, dirty Dio-Sol thinner and the sludge that collects on the bottom of the bottle, was brushed on the sanded deck. The deck now had the aged look; however, spaces between boards were almost gone. The back of a #11 blade in a Xacto knife was used as a scriber to bring them back.

To give the deck an even better wood look, I went over the deck with a Minwax Wood Finish stain marker, #211, provincial color, purchased at the local home improvement store.

After the deck dried I added the steel plates the GN added to the deck above the bolsters and on the deck ends. Ted Frandel’s article suggested removing molded boards above the bolsters and from the deck ends. I thought that would be quite difficult. Therefore, steel plates were cut from Evergreen .005” sheet styrene and glued with MEK to the deck in appropriate locations. The steel plates dimensions were three boards wide above the bolsters and two boards wide on the ends. The steel plates were painted with Model Master Steel #1780, steel.

The car was ready for weathering. I used the following Pan pastels to weather the car with makeup brushes and micro applicators: Red Iron Oxide Extra Dark 380.1 on car body, Payne’s Grey Extra Dark 840.1 on car body, under body and trucks. Red Iron Oxide Shade 380.3 on trucks and couplers.

At this point I had a good stand in flat car that with additional changes made in the Ted Frandel article would be a close match to the prototype. The easy change was to replace the incorrect trucks with correct Tahoe Model Works, TMW-101, Dalman trucks.

Not so easy to make the change on the “B” end. I removed the brake gear and grab iron on the left side in the incorrect location and relocated them to the correct location. The drop brake shaft was cut off and replaced with a longer brake shaft, Tichy #1102, .015” PBW. A Tichy brake wheel from set #3013 was installed since I had broken the kit provided one during removal.

A needed number change from the current number 69158 to place the car in the correct series was next. A Eurotool micro scratch brush was used to remove the number. The area was touched up with a close car body matching Vallejo Model Color paint mix of Mahogany Brown #70.846, 3 drops or 43%, Cavalry Brown #70.982, 1 drop or 14%, and Black Red 3 drops or 43%. And, the paint was quickly dried with a hair dryer to enable a Vallejo Satin #70.522, to be applied to provide a decal base. Decals with numbers matching in size to the removed numbers came from a Grand Trunk Western set. I chose 69958 for the car number applied with MicroScale Micro Sol. After setting overnight the decals and area were brushed with Vallejo Matt Varnish #70.520.

After making these changes to the car body I decided I would go back to the under body to complete adding most missing details. Yes, visitors will probably never see it; however, I will have the satisfaction of knowing it is there. Therefore, the following details were added:

- slots were made in the center sill for brake levers using drill and broach

- brake levers made from Evergreen strip styrene

- brake lever hangers, Branchline plastic grab irons from parts box

- piping from air reservoir to control valve, Tichy #1101, .010” diameter PBW

- pipe from brake cylinder to control valve, Tichy #1106, .0125” diameter PBW

- brake rods, Tichy #1106, .0125” diameter PBW

- brake rod clevises, MEK Goop

- chain, A-Line #29219, Black 40 links per inch

I now went back to the ends and installed the uncoupling levers and eye bolt brackets made from Tichy #1101, .010" diameter PBW. I like to install them as the last detail item on any build as if I install them sooner I seem to catch them and bend or break them while still working on the car.

|

| "B" end with uncoupling lever installed. |

Car weathered again to match changed details and areas to the rest of car.

Once weathered the car was put into revenue service on my Minneapolis & Northland Railroad Company.

|

| Great Northern Flat Cat 69958 sitting at Tunnel City Minneapolis & Northland Railroad Company Team Track ready for pickup after it's lumber load has been unloaded. |

"Thank You" Rich Remiarz and Bob Heninger for the information to help with build of GN Flat 69958 and Rich for the article and car diagram to provide the changes needed to the Red Caboose Flat Car to match a GN prototype.

Thank You for taking time to read my blog. You can share a comment in the section below if you choose to do so. Please share the blog link with other model railroaders.

Lester Breuer

No comments:

Post a Comment