The next day I began to research the prototype. In Railway Prototype Cyclopedia 9, page 60, I found a photo of RI hopper 89589 from series 89500-89599, after the homemade covered roof was added by the Rock Island Shops in 1945. Steve Hile provided me with a Rock Island Lines shop diagram for the 50 ton 33 ft. covered hopper cars. The diagram shows the shop made roof with three hatches and the 9-10 inch diameter holes for grit loading that were later covered with circular plates.

In response to a post on RealSTMFC regarding Rock Island hopper decals, I learned about and found the article by Martin Lofton in July 1987 Mainline Modeler with prototype history, photos and how-to steps for scratch building the roof. After reading the article I decided to make a roof master as Bob Massey did and make a rubber mold of the master to make a resin cast removable roof rather than make a permanently attached plastic covered car roof as Martin described in his article. A removable roof would allow me to run the hopper car as a A.A.R. class HM hopper without the roof and a A.A.R. class HMR, later changed to LO, hopper with the roof. The roof would sit on an upgraded Athearn hopper kit obtained at a local train show. The upgrade of the Athearn hopper car is described in a January 2019 post on my blog titled, “Rock Island Hopper 89502.”

I used a box car with a Murphy panel roof panels to make the master , a rubber mold, and a resin casting of the roof.

Triangular brace extensions on the roof sides supporting the roof on the hopper sides were cut from Evergreen, #8210, 2x10” strip styrene. A Northwest Short Line chopper was used to cut 10x10” squares from the Evergreen strip. The squares were then cut from corner to opposite corner with a single edge razor blade (SERB) creating a triangle side brace extension. The triangle brace extensions are glued on the roof sides in line with the roof ribs. The triangular brace extensions support the removable roof when placed on the open top hopper.

I added rivets on roof ends with Archer 5/8” rivets, AR88026, using Future floor finish and CA to secure them.

Resin running boards from the parts box were installed. Longitudinal running board extension brackets were made from Evergreen, #8103, 1x3” strip styrene. Prior to install, latitudinal running boards had mounting brackets cut from .005”x .030” shim brass glued to the back with extensions on the back side for gluing under the longitudinal running board and extensions on the front edge for bending over the roof edge. And, before install, I added corner grab irons bent from Tichy Train Group (Tichy), #1100, .010” diameter phosphor bronze wire (PBW) with Yarmouth Model Works shoulder eyebolts, YMW #356, for corner brackets. Installing the grab irons on the latitudinal running boards prior to install makes it easy to cut off any wire protruding through the back flush with the backside.

I added rivets on roof ends with Archer 5/8” rivets, AR88026, using Future floor finish and CA to secure them.

|

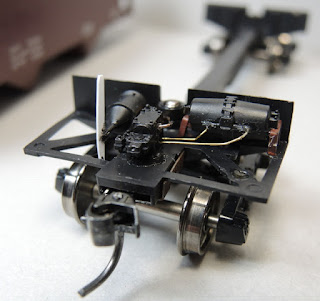

| Triangular brace extensions on roof sides added to support roof and Archer rivets applied to ends. |

Resin running boards from the parts box were installed. Longitudinal running board extension brackets were made from Evergreen, #8103, 1x3” strip styrene. Prior to install, latitudinal running boards had mounting brackets cut from .005”x .030” shim brass glued to the back with extensions on the back side for gluing under the longitudinal running board and extensions on the front edge for bending over the roof edge. And, before install, I added corner grab irons bent from Tichy Train Group (Tichy), #1100, .010” diameter phosphor bronze wire (PBW) with Yarmouth Model Works shoulder eyebolts, YMW #356, for corner brackets. Installing the grab irons on the latitudinal running boards prior to install makes it easy to cut off any wire protruding through the back flush with the backside.

Roof hatches cast from resin using Sunshine Models PFE Reefer hatches from kit 46.4 for the master were installed. A Grandt Line Std. Guage Reefer Hardware set, #5106, contains hatches that could be used. Next each hatch received a handle bent from Tichy, #1101, .010” diameter PBW and a wood hatch rest next to the handle made from scrap strip styrene. Roof hatch rests, wood on the prototype, were made from Evergreen, #8202, 2x2” strip styrene. The 9” hole covers were cut from a 9” diameter kit sprue with a single edge razor blade (SERB) and sanded to final thickness before install.

The covered hopper roof was now moved to the paint shop where it was sprayed with a Vallejo mix of two parts Model Color Black red, 70.859, and one drop Model Color Flat Yellow, 70.953. Once dry, I sprayed the roof with Model Master Flat Clear Acryl. After drying I weathered the roof with Pan Pastels: Burnt Sienna, 740.5 and Payne’s Grey Tint, 840.7. I do not spray any protective coat to protect the weathering as I have found it is not necessary after seeing cars handled in numerous operating sessions with no finish problems.

The Rock Island hopper removable roof can be put on open top RI hopper 89502 to turn it into a covered hopper, A.A.R. class HMR, later changed to “LO.”

I want to thank Steve Hile for sharing the Rock Island diagram for 50 ton 33 ft. Covered hoppers with me and allowing me to share it with you in this post.

Thank You for taking time to read my blog. You can share a comment in the section below if you choose to do so. Please share the blog link with other model railroaders.

Lester Breuer